Stereolithography File Viewer

For other uses, see. STL (an abbreviation of 'stereolithography') is a native to the software created. STL has several after-the-fact such as 'Standard Triangle Language' and 'Standard Language'. This file format is supported by many other software packages; it is widely used for, and.

How can the answer be improved? STL (STereoLithography) is a file format native to the stereolithography CAD software created by 3D Systems.[1][2][3] STL has several after-the-fact backronyms such as 'Standard Triangle Language' and 'Standard Tessellation Language'.[4] This file format is supported by many other software packages; it is widely used for rapid prototyping, 3D. In-stl - InSTL - Stereolithography file viewer and editor #opensource.

STL files describe only the surface geometry of a three-dimensional object without any representation of color, texture or other common CAD model attributes. The STL format specifies both and representations. Binary files are more common, since they are more compact. An STL file describes a raw unstructured surface by the and vertices (ordered by the ) of the triangles using a three-dimensional.

In the original specification, all STL coordinates were required to be positive numbers, but this restriction is no longer enforced and negative coordinates are commonly encountered in STL files today. STL files contain no scale information, and the units are arbitrary. Contents. ASCII STL An ASCII STL file begins with the line solid name where name is an optional string (though if name is omitted there must still be a space after solid). The file continues with any number of triangles, each represented as follows: facet normal n i n j n k outer loop vertex v1 x v1 y v1 z vertex v2 x v2 y v2 z vertex v3 x v3 y v3 z endloop endfacet where each n or v is a in sign-'e'-sign- format, e.g., '2.648000e-002'.

The file concludes with endsolid name The structure of the format suggests that other possibilities exist (e.g., facets with more than one 'loop', or loops with more than three vertices). In practice, however, all facets are simple triangles. White space (spaces, tabs, newlines) may be used anywhere in the file except within numbers or words. The spaces between 'facet' and 'normal' and between 'outer' and 'loop' are required. Binary STL Because ASCII STL files can become very large, a binary version of STL exists.

A binary STL file has an 80-character header (which is generally ignored, but should never begin with 'solid' because that will lead most software to assume that this is an ASCII STL file ). Following the header is a 4-byte unsigned integer indicating the number of triangular facets in the file. Following that is data describing each triangle in turn. The file simply ends after the last triangle.

Free File Viewer Download

Each triangle is described by twelve 32-bit floating-point numbers: three for the normal and then three for the X/Y/Z coordinate of each vertex – just as with the ASCII version of STL. After these follows a 2-byte ('short') unsigned integer that is the 'attribute byte count' – in the standard format, this should be zero because most software does not understand anything else. Floating-point numbers are represented as numbers and are assumed to be, although this is not stated in documentation. StereoLithography Interface Specification, 3D Systems, Inc., July 1988.

StereoLithography Interface Specification, 3D Systems, Inc., October 1989. SLC File Specification, 3D Systems, Inc., 1994. Grimm, Todd (2004), p. 55,.

Many names are used for the format: for example, 'standard triangle language', 'stereolithography language', and 'stereolithography tesselation language'. Page 55 states, ', the inventor of stereolithography and 3D Systems' founder, reports that the file extension is for stereolithography.' (2003), Rapid Prototyping: Principles and Applications (2nd ed.), World Scientific Publishing Co, Chapter 6, Rapid Prototyping Formats. Page 237, 'The STL (STeroLithography) file, as the de facto standard, has been used in many, if not all, rapid prototyping systems.'

Section 6.2 STL File Problems. Section 6.4 STL File Repair. ^ Burns, Marshall (1993). Automated Fabrication. Prentice Hall.

Fabbers.com, The StL Format: Standard Data Format for Fabbers, reprinted from Marshall Burns, Automated Fabrication, stating, 'The object represented must be located in the all-positive octant. In other words, all vertex coordinates must be positive-definite (nonnegative and nonzero) numbers.

The StL file does not contain any scale information; the coordinates are in arbitrary units.' 17 November 2016. Retrieved 5 May 2017. Retrieved 5 May 2017. Hiller, Jonathan D.; Lipson, Hod (2009).

Cornell University. Retrieved 5 May 2017. External links.: Standard Data Format for Fabbers.: List of software to work with STL file.

The STL file is the standard file format needed for 3D Printing and purposes. Very much like the TXT file format used in desktop publishing, the STL file allows users to print and make copies of their designs (via 3D printing) using a wide variety of 3D CAD software.

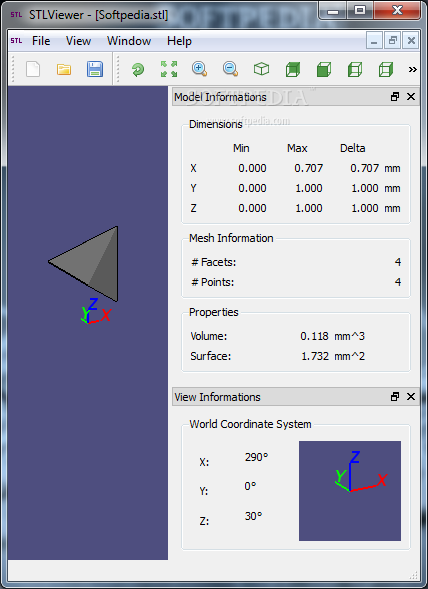

The STL file is opened by the 3D printers unique software interface. This software will “slice” the model in precise layers, and translate that information into the tool paths that will physically create the design layer by layer. The picture to the right, is an example of how the software slices the STL file.

Note that this picture is being used to show the software’s processing of the STL file. The actual orientation and build plane would be chosen differently for efficiently 3d printing this Design. Almost all professional 3D CAD platforms have the ability to “export-as” or “save-as” an STL format.

It is very important to check your export options and ensure that the STL file will be created at high resolution with low tolerance of surface deviation. This ensures geometric accuracy.

The is translating a unique code and making it interchangeable for 3D printing and rapid prototyping purposes, the proper resolution settings and units of measure are critical to a quality result. As the popularity of 3d printing has grown in industry and manufacturing, many 3D CAD platforms can now “import” an STL file that can be then converted to a base solid.

This allows the base solid to be modified mainly for streamlining the rapid prototyping and 3d printing process. This is a very nice feature to have when you work with 3d printing technology that requires the STL format and leads to much higher productivity.

Generally, creating an STL file is a simple process provided that the user is familiar with 3D CAD and the concepts of rapid prototyping. However, sometimes issues do arise in the translation process even for the professional user.

Faces and features can be literally “lost in translation.” We are happy to assist clients in getting the proper STL needed to 3D print their designs, simply Contact Us with any questions. STL (STereoLithography) is a native to the software created.